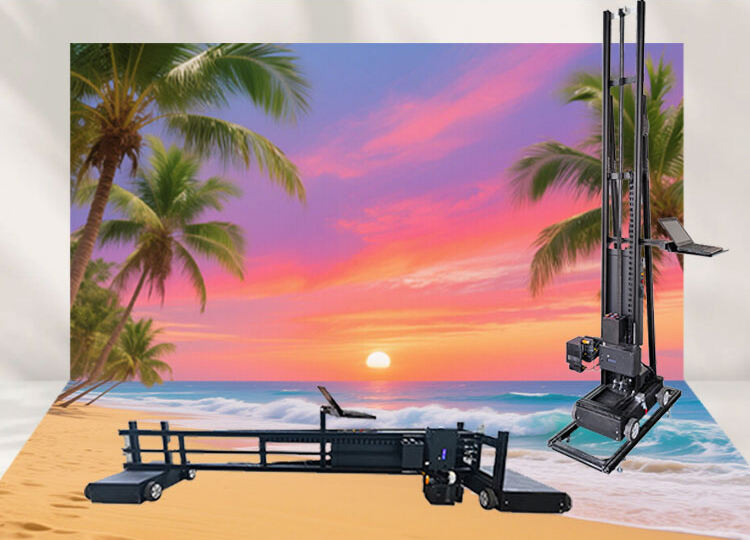

In the field of floor decoration and signage, traditional processes are often limited by material handling and fixed layouts. However, the 3D floor painting robot, with its core advantages of on-site printing and multi-material adaptability, has become an innovative device that breaks down industry barriers. Leveraging UV curing technology, it uses precise inkjet and instant curing to create creative designs directly on a variety of floor substrates. Combining practicality and aesthetics, it is widely used in commercial spaces, public areas, and personalized settings.

Core Features: Dual Guarantee of Technology and Performance

The device utilizes five UV-curable inks (CMYK + white) as base colors. Its specialized inkjet printhead achieves precise color mixing and spraying, reproducing rich color gradations and intricate pattern details. Paired with SAi FlexiPrint RIP software, it efficiently converts imported images into machine code. The software supports 11 languages and boasts powerful image detail reproduction capabilities, ensuring professional and clear print results. The wheeled design provides flexible mobility and unlimited vertical expansion. The default horizontal printing width reaches 2.3 meters (with a 2.7-meter segmented guide rail for easy transport), and can be expanded to 3.3 meters with a 1-meter extension pole to meet the needs of various applications.

Scenario Adaptability: Unlimited On-Site Printing Capabilities

Unlike traditional flatbed printers that require fixed materials for printing, the 3D floor painting robot can operate directly on-site, making it particularly suitable for immobile floor substrates. It can reliably print on indoor wood, tile, and epoxy floors, as well as outdoor concrete, brick, and limestone surfaces. Examples include epoxy parking signage in commercial spaces, branding on shopping mall floors, cultural graffiti on outdoor streets, and guideposts in parks. No substrate removal or handling is required, significantly reducing construction complexity and costs. The dual sensors at the nozzle automatically detect the distance from the ground, maintaining optimal printing distance even on slightly uneven surfaces, preventing nozzle collisions and ensuring a stable printing process. Durability Treatment: Practical Design for Complex Environments

Floor printing products must withstand wear and tear and environmental challenges. This equipment utilizes a dual pre-treatment and post-treatment process to ensure durability. Pre-treatment uses a coating to enhance ink adhesion and prevent fading. Post-treatment spraying with a clear coating enhances image brightness, significantly increases wear resistance, and protects against outdoor rain damage. Thanks to the properties of UV ink, indoor printed images remain colorfast for eight years. Despite the effects of UV rays, outdoor images retain clarity for over two years under normal use, meeting the lifespan requirements of various applications.

From commercial decoration to public signage, from personalized interior design to outdoor scene creation, the 3D floor painting robot, with its on-site printing, multi-material adaptability, durability, and efficiency, offers a new solution for the floor decoration industry. Whether enhancing the visual impact of a space or implementing functional signage, its flexible and convenient operation allows creative ideas to be quickly transformed into tangible floor art.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

TH

TH

TR

TR